Views: 16

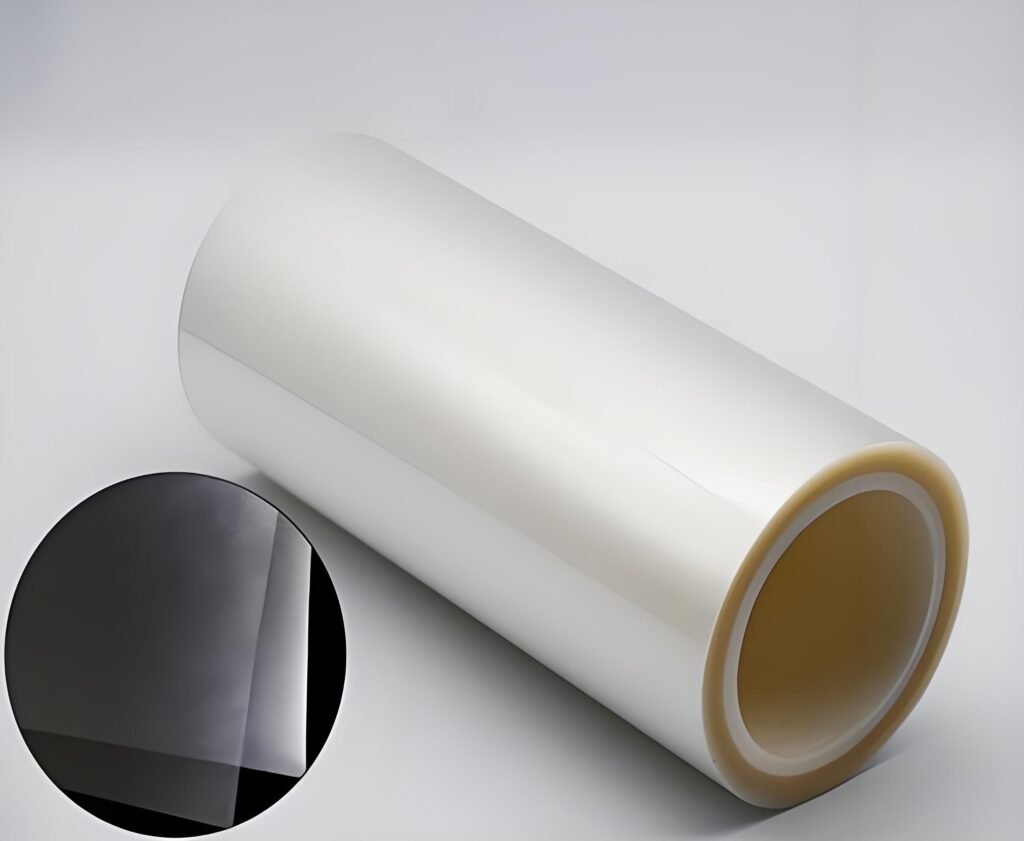

Release film is a thin film material with special separation properties on the surface, which is widely used in industrial production and many fields. Release film is a silicone release agent coated on the surface of environmentally friendly PET/PE/OPP film, which allows it to show extremely light and stable release force for various organic pressure-sensitive adhesives. Different organic pressure-sensitive adhesives, such as hot melt adhesives, acrylic adhesives and rubber system pressure-sensitive adhesives, require different release film release forces.

Classification by release force

1.Light release film: peeling force is below 0.10N/25mm, suitable for applications requiring extremely light peeling force.

2.Medium release film: peeling force is below 0.20N/25mm, suitable for applications with general peeling force requirements.

3.Heavy release film: peeling force is between 0.35~0.45N/25mm, suitable for applications requiring strong peeling force.

Classification by material includes : PET release film (polyester release film), BOPP release film (polypropylene release film), PTFE release film (polytetrafluoroethylene release film), ETFE release film (fluorine-resistant release film), FEP release film (Teflon release film) and many other types.

Classification by surface treatment includes : single-sided silicone release film, double-sided silicone release film, silicone-free release film, fluorine release film, single-sided corona release film and many other types.

Classification by color includes : transparent release film, translucent release film, blue release film, yellow release film, red release film, green release film and so on.

According to the structure, it can be divided into adhesive release film, adhesive-free release film, composite release film (i.e. the base material of the release film is a composite of two or more materials), etc.

According to the function of the release film, it can be divided into isolation release film, filling release film, protection release film, light diffusion film, printing film, sandblasting film, drawing film, etc.

Common release films and their uses:

| Release film types | uses |

| Low-pressure polyethylene HDPE release film | used for waterproof rolls such as sealing tapes, etc |

| LDPE high-pressure polyethylene release film | used for mechanical product packaging, hot melt adhesive packaging, sanitary care products (diapers), anti-corrosion rolls, etc. |

| Stretch polypropylene BOPP release film | used for sealing tapes, silent tapes, etc. |

| Stretch polyester PET release film | adhesive protection, etc. |

| Red/green polyolefin double-sided release film | used for foam tape |

| Transparent PET double silicon release film | double-sided adhesive |

| Sun-resistant isolation film, HDPE silver coating film | waterproof roll for sun protection and cooling |

| Enhanced aluminized substrate BOPP enhanced/BOPET enhanced | improves the adhesion of the aluminized layer and makes it resistant to 100°C boiling, mainly used in the electronics industry, adhesive industry, rubber industry, automotive industry and pharmaceutical industry. |