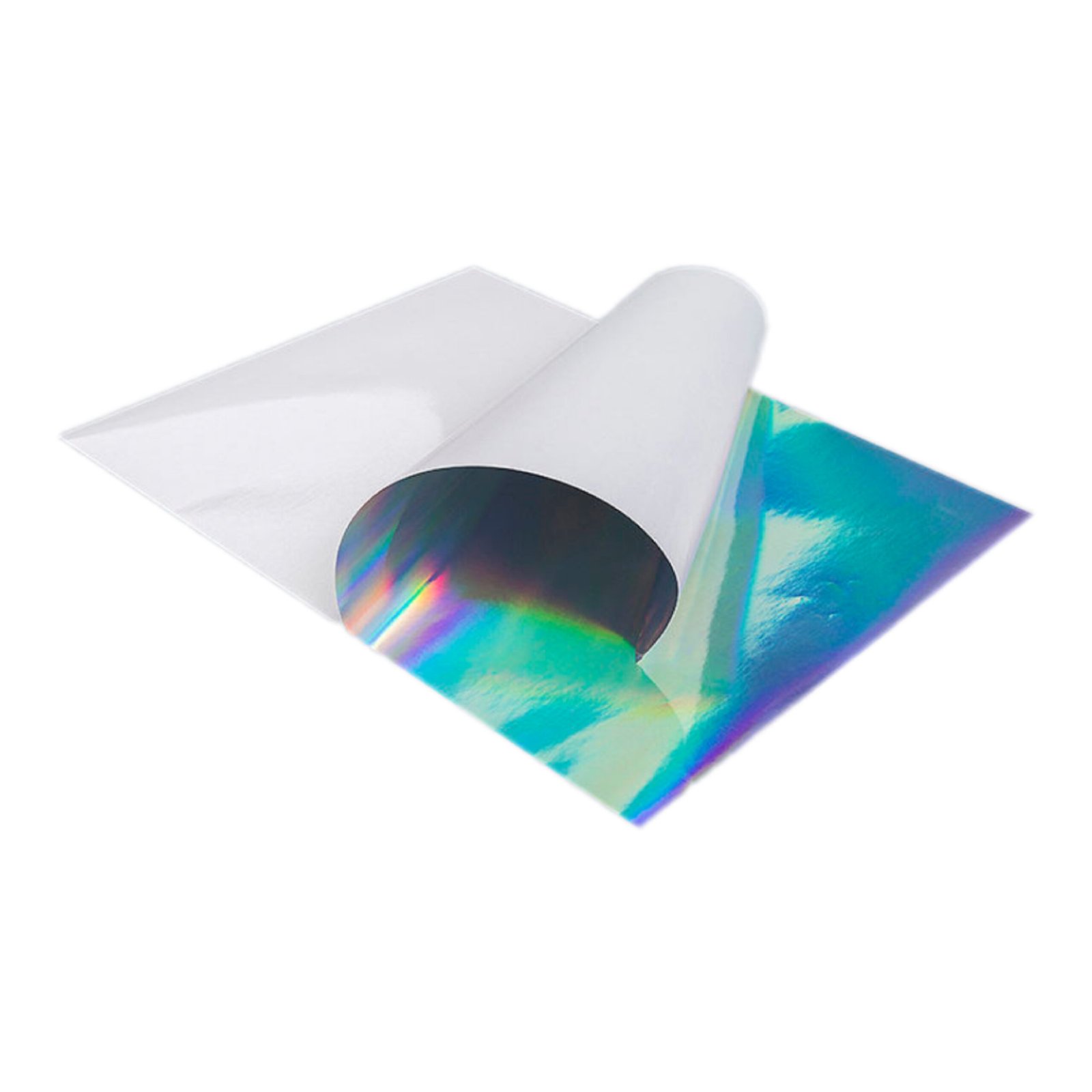

Charmetack’s PE Self-Adhesive Protective Film acts as a robust barrier for your materials during fabrication, transport, and installation. Engineered with a pressure-sensitive adhesive system, our film ensures stable adhesion while guaranteeing clean, residue-free removal.

Whether you need to protect high-gloss plastic, brushed stainless steel, or coated aluminum profiles, we provide customized adhesion solutions direct from our factory to match your specific surface energy.

Why Choose Charmetack Protective Film?

- Zero Residue Guarantee: Our water-based acrylic and rubber-based adhesive formulas are designed to peel off cleanly, saving you from costly cleaning labor.

- Customized Adhesion (5g - 800g): We don't guess. We tailor the peel strength to your surface roughness to ensure the film doesn't fall off during cutting or stick too hard during removal.

- Heavy-Duty Durability: Made from high-quality LDPE/LLDPE, offering excellent puncture and tear resistance against scratches, dust, and minor impacts.

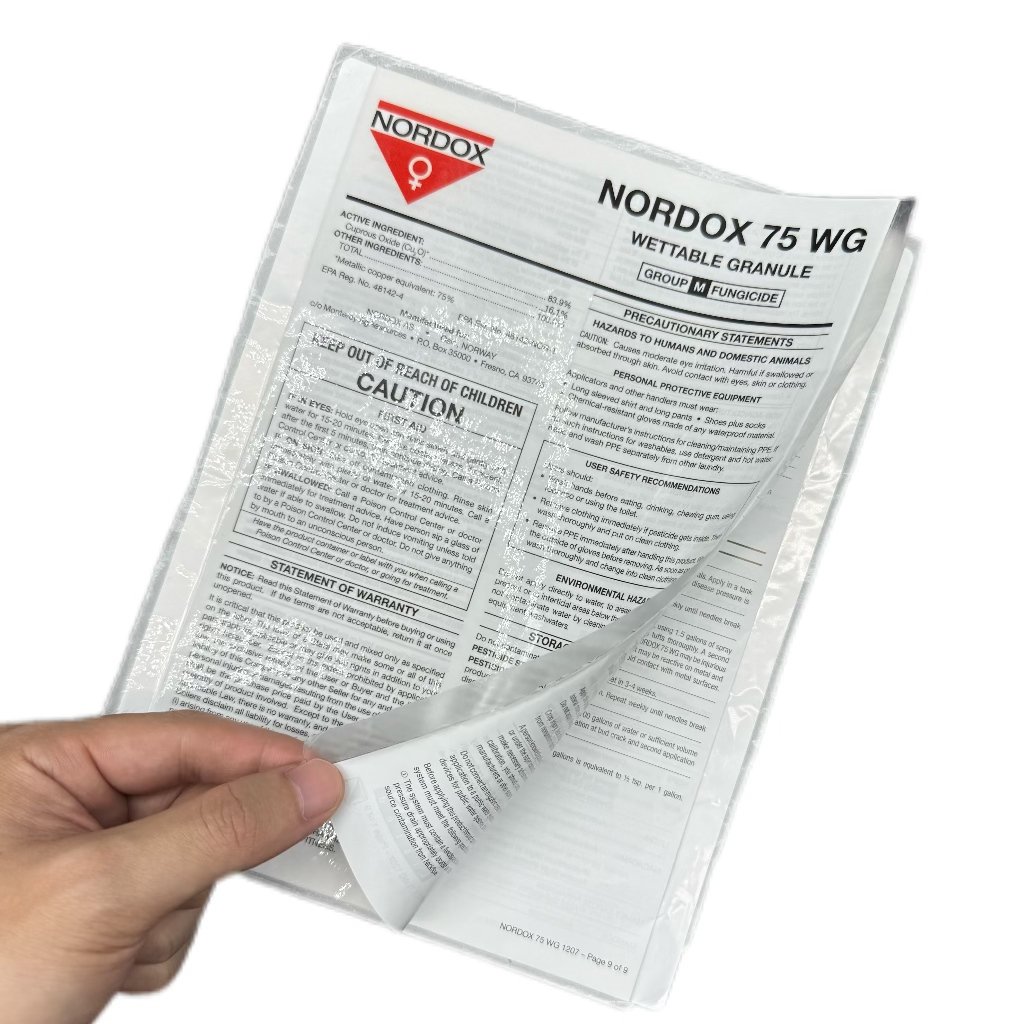

- Brand Promotion: Available with custom rotogravure printing (up to 3 colors) to display your logo, branding, or directional arrows.

Technical Specifications

We offer a wide range of customization options to suit different industrial applications.

| Property | Specification Range |

| Base Material | Polyethylene (LDPE / LLDPE Blend) |

| Adhesive System | Water-based Acrylic / Solvent Acrylic / Rubber-based |

| Thickness | 30 – 120 microns (1.2 – 4.7 mil) |

| Width | Up to 1600 mm (Custom Slitting Available) |

| Roll Length | 100 m – 2000 m per roll |

| Adhesion Strength | Customizable: • Low Tack: Glass, Glossy Plastic • Medium Tack: Aluminum, Stainless Steel • High Tack: Carpet, Textured Surfaces |

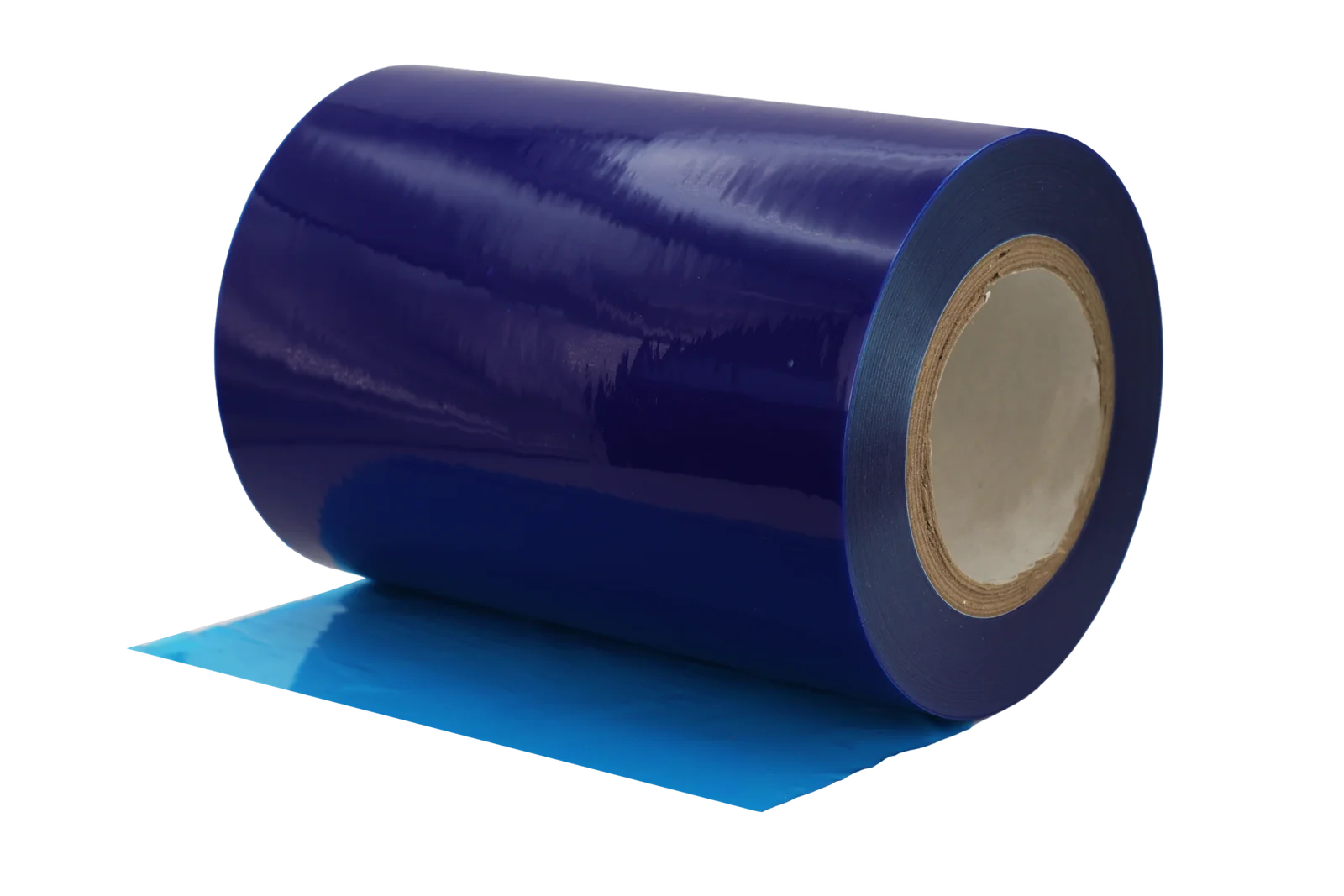

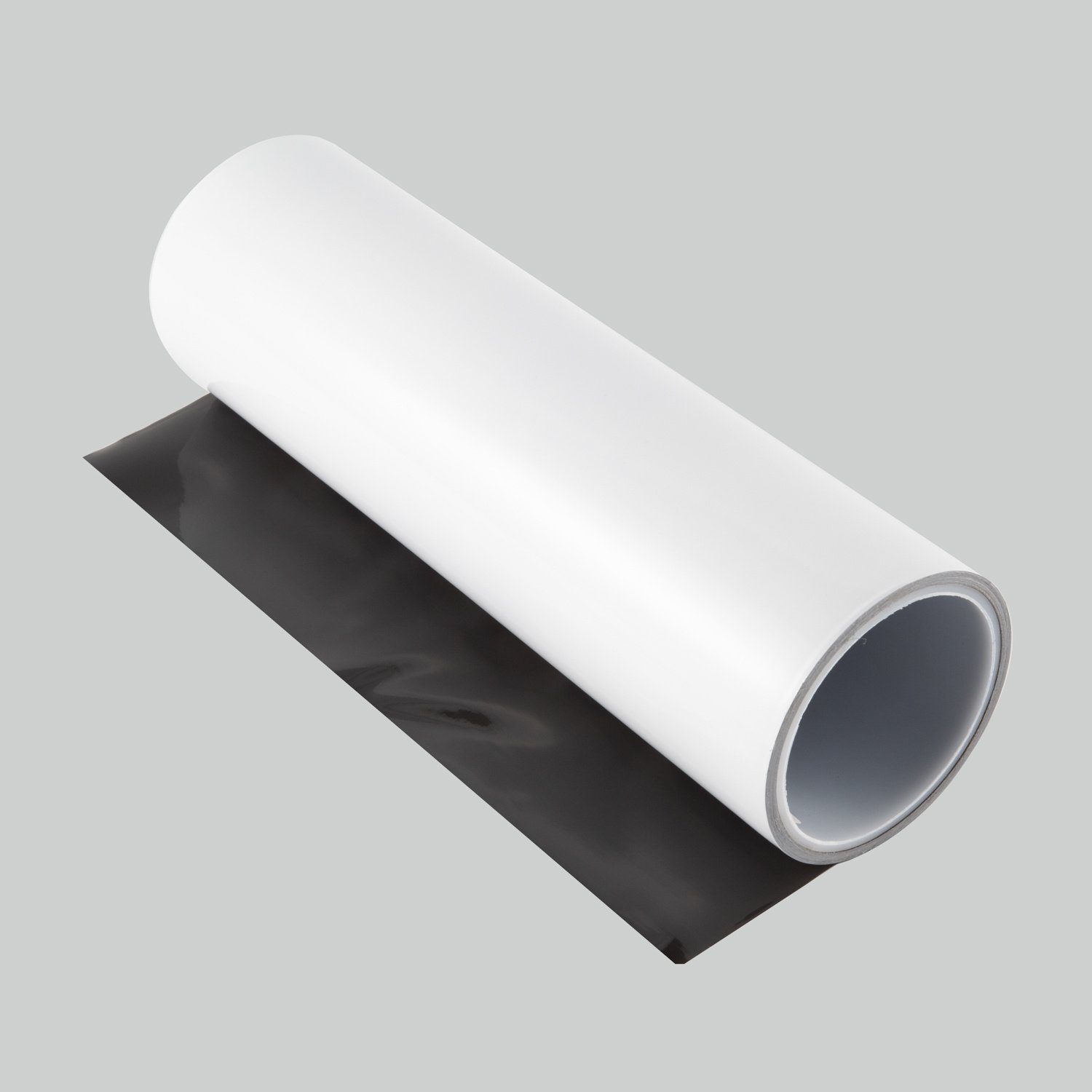

| Colors | Clear (Transparent), Blue, Milky White, Black & White, Green |

| Print Capability | Yes (Logo / Instructions / Arrows) |

| UV Resistance | Available on request (Up to 6 months outdoor life) |

Typical Applications

Our films are trusted across industries to protect surfaces from the production line to the end-user:

- Metals: Stainless steel (Mirror/Brushed), Aluminum profiles, Sandwich panels, Color-coated steel coils.

- Plastics: Polycarbonate (PC) sheets, PMMA Acrylic, PVC profiles, Injection molded parts.

- Glass & Glazing: Windows, Doors, Curtain walls, Mirrors.

- Building Materials: High-pressure laminates (HPL), Wooden flooring, Ceramic tiles, Carpets.

- Furniture: High-gloss kitchen cabinets, Decorative panels.

How to Choose the Right Film?

Choosing the wrong adhesion level can lead to residue or film lifting. Consider these factors:

- Surface Texture: Glossy surfaces require Low Tack; Rough/Textured surfaces require High Tack.

- Processing: Will the material undergo laser cutting, bending, or deep drawing? (We have special films for these).

- Environment: Is it for indoor storage or outdoor exposure (UV required)?

Not sure? Contact us for a free consultation and sample testing.

FAQ: PE Protective Film

Q: Will the film leave residue glue on my product?

No. Provided the correct film grade is selected for your surface type, our formulation guarantees clean removal. We always recommend testing a sample first.

Q: Can you print our company logo?

Yes, we offer custom rotogravure printing. We can print your logo, brand name, or technical instructions in up to 3 colors to enhance your brand image.

Q: What is the lead time for orders?

For standard clear/blue films, lead time is 7-10 days. For custom printed films, allow 15-20 days for the first order (due to cylinder making).

Start Your Project with Charmetack

Looking for a reliable factory partner? Get a competitive quote and free samples today.

Please provide: Surface Type + Dimensions + Estimated Quantity.