The Solution for Bubble-Free Lamination and Application.

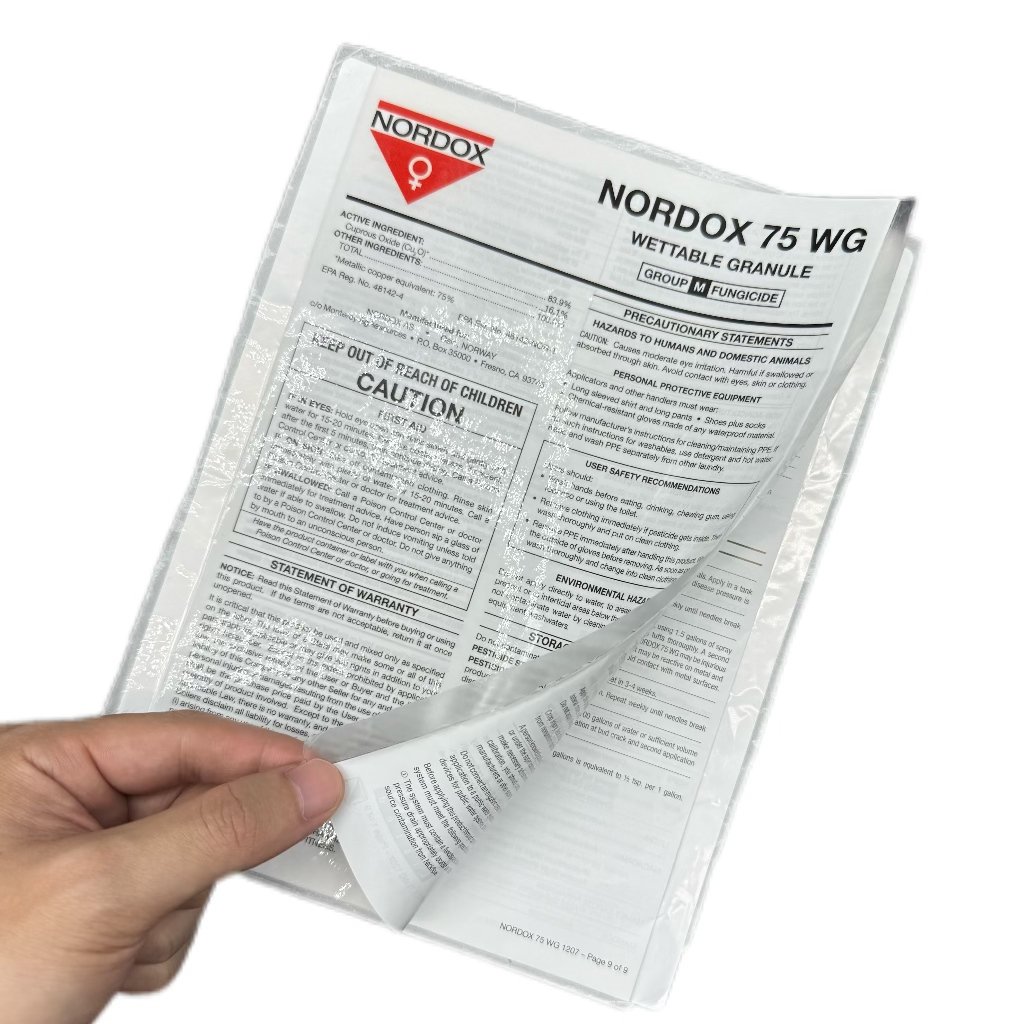

Charmetack’s Embossed (Air Groove) Release Paper is engineered with precise micro-structured patterns pressed into the PE coating. These patterns transfer a negative texture to the adhesive surface, creating physical "air channels" that allow trapped air to escape during application.

Combined with our uniform silicone coating technology, this liner delivers consistent release performance and high dimensional stability, making it the industry standard for Car Wraps, Air-Free Vinyls, and high-performance industrial tapes.

Key Features & Benefits

- Excellent Air Exhaust: The embossed grooves effectively eliminate bubbles during manual application (e.g., vehicle wrapping) or industrial lamination.

- Uniform Silicone Coverage: Specialized coating techniques ensure silicone covers both the "peaks" and "valleys" of the embossing, preventing adhesive lock-up.

- High Stiffness: The PE-coated base (up to 250gsm) provides the rigidity needed for stable die-cutting and high-speed automatic dispensing.

- Custom Release Profiles: We can tune the release force from Ultra-Light (1g) for easy peel to Super-Heavy (300g+) for differential release tapes.

Technical Specifications

| Property | Details |

| Base Color | White, Yellow, Natural Kraft (Brown) |

| Basis Weight (GSM) | 110 g/m² – 250 g/m² |

| Roll Width | 500 mm – 1540 mm (Customizable slitting) |

| Release Force Range | • Super Light: 1g – 3g • Light: 3g – 5g • Regular: 10g – 15g • Heavy: 30g – 50g • Super Heavy: 300g+ |

| Printing | Single-color backside printing available (Logo/Grid) |

Typical Applications

1. Vehicle Wraps & Graphics

Essential for color-change films and car stickers, ensuring a smooth, bubble-free finish on curved surfaces.

2. Foam & Double-Sided Tapes

Improves lamination efficiency by allowing air to escape between the adhesive and the carrier foam.

3. Electronic Components

Used as a carrier for precision die-cut parts where stability and flatness are critical.

Request a Sample or Quotation

Our engineers will match the optimal Embossing Pattern and Release Force for your adhesive.

Please specify: End-Use Application + Target GSM + Release Force

-1-scaled.jpg)

-scaled.jpg)

-scaled.jpg)

-scaled.jpg)

-scaled.jpg)

-1.jpg)

.jpg)