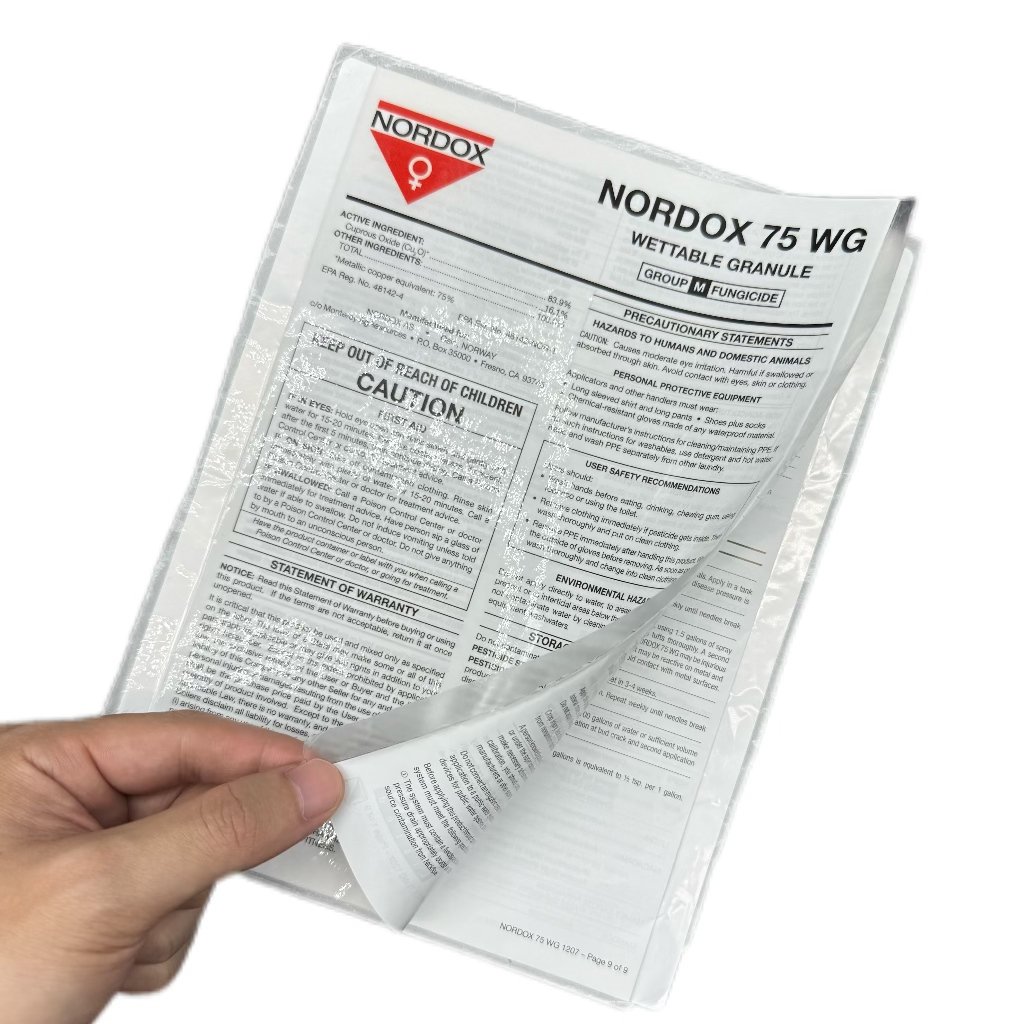

Electronic & Electrical Label Materials (UL Compliant)

Safety, Durability, and Compliance for the Electronics Industry.

Charmetack’s Electronic Label Materials are engineered to survive the entire product lifecycle—from the extreme heat of SMT reflow soldering (+280°C) to the long-term wear on outdoor appliance nameplates.

Fully compliant with **UL 969, RoHS, and REACH** standards, our self-adhesive films ensure that your safety warnings and serial numbers remain legible on PCBs, batteries, and power supplies.

Select Your Application Material

| Category | Material & Features | Temp Range |

| 1. High-Temp PCB Labels (Kapton® Alternative) |

Material: 25µm / 50µm Polyimide (PI) Film (White/Amber) Feature: Survives SMT Reflow & Wave Soldering. Chemical resistant to board cleaners. Anti-static (ESD) options available to protect sensitive chips. |

-40°C to +300°C |

| 2. Appliance Nameplates (UL 969 Standard) |

Material: 50µm Polyester (PET) (Silver/White/Matte) Feature: Replaces metal plates. High shear adhesive bonds permanently to powder-coated metals and LSE plastics. Tear-proof and solvent resistant. |

-40°C to +150°C |

| 3. Battery & Cable Labels |

Material: Flame Retardant PP / Soft PVC Feature: Flexible and conformable. Used for battery wrapping and cable flagging. VTM-0 Flame Retardant grade available. |

-20°C to +80°C |

Technical Specifications

Formulated for strict industrial requirements.

| Parameter | Details |

| Adhesive Types |

• Silicone: For extreme heat (PCB masking/labeling). • Acrylic: High transparency & permanent bonding (Standard). • Conductive: Optional for EMI shielding applications. |

| Special Features |

• Halogen-Free: Environmentally friendly for green electronics. • Bubble-Free: Air-egress channels for large battery labels. • Tamper-Evident: "VOID" residue for warranty seals. |

| Printability | Thermal Transfer (Resin Ribbon), UV Inkjet, Screen Printing. |

| Certifications | UL 969 Recognized, RoHS 3.0, REACH, ISO 9001. |

FAQ: Electronic Label Materials

Q: Do you have a substitute for Kapton® labels?

Yes. Our Polyimide (PI) Series offers the same thermal performance (up to 300°C) and chemical resistance as branded Kapton, but at a more competitive factory-direct price.

Q: Can your labels stick to rough powder-coated metal?

Absolutely. For powder-coated appliance casings, we recommend our High-Tack Acrylic Adhesive (Coat weight >30gsm), which is specifically formulated to bond to textured, low-surface-energy (LSE) materials.

Ensure Compliance for Your Electronics

Get Free Samples for UL/Reflow Testing.

Tell us: Application (PCB/Housing/Battery) + Temp Requirement