Views: 2

Release paper is a cornerstone of adhesive technology, enabling the seamless application of labels, tapes, and a myriad of other products across countless industries. At Charmetack, we have established ourselves as leading custom release paper manufacturers, delivering tailored solutions that meet the precise needs of our clients. With years of expertise and a commitment to innovation, our release paper products are engineered to provide exceptional performance, reliability, and versatility. In this extensive exploration, we delve into the professional intricacies of our release paper offerings, spotlighting the technical parameters that define their quality and the diverse applications they serve. Whether you’re a label printer seeking precision or an industrial manufacturer requiring durability, Charmetack’s release paper is designed to elevate your operations.

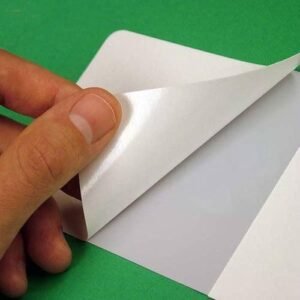

So, what exactly is release paper? At its core, release paper—often referred to as a release liner—is a specialized paper coated with a release agent, typically silicone, that prevents adhesives from bonding permanently to its surface. This unique property allows adhesive-backed materials, such as labels or tapes, to be easily peeled away without compromising their stickiness or leaving unwanted residue. The result is a product that balances temporary adhesion with clean separation, making it indispensable in industries ranging from packaging and automotive to medical and food production. At Charmetack, we take this fundamental concept and enhance it with advanced manufacturing techniques and customizable options, ensuring our release papers meet the highest industry standards.

Our journey as custom release paper manufacturers begins with our diverse product portfolio, crafted to address a wide spectrum of adhesive needs. Among our flagship offerings are products like Glassine Release Paper, Kraft Release Paper, Clay-Coated Kraft Release Paper, and Specialty Release Paper—each designed with specific technical attributes to excel in targeted applications. For instance, our Glassine Release Paper features a smooth, translucent glassine base paper coated with silicone, offering a release force ranging from 5 to 50 grams per inch (g/in). This makes it an ideal choice for high-speed labeling applications where consistent peeling and minimal resistance are paramount. Meanwhile, our Kraft Release Paper, built on a robust kraft base, provides a higher release force of 20 to 100 g/in and a thickness range of 80 to 150 microns, catering to heavy-duty industrial adhesives that demand strength and stability.

Diving deeper into our product range, the Clay-Coated Kraft Release Paper stands out for its refined surface and enhanced printability. With a release force of 10 to 80 g/in and a thickness between 70 and 120 microns, this product is favored in premium labeling applications where aesthetics and performance converge. For more specialized needs, our Specialty Release Paper offers unparalleled flexibility. Available with non-silicone coatings and customizable release forces, it serves industries like medical and food packaging, where safety and regulatory compliance are critical. Curious about our full lineup? You can explore detailed descriptions and specifications on our products page, where we showcase how each release paper is tailored to solve unique challenges.

The technical parameters of our release papers are what truly set Charmetack apart as a leader in this field. Let’s start with the base paper—the foundation of any release liner. We source only premium-grade materials, such as glassine, kraft, and clay-coated kraft, to ensure durability and functionality. Glassine, for example, is prized for its smoothness and semi-transparency, allowing for precise adhesive application and visibility where needed. Kraft paper, on the other hand, brings superior tensile strength, making it suitable for rugged environments. Each base paper is selected based on the end-use requirements, and we offer customization options to adjust weight and texture to your specifications.

Next, the coating technology is a critical factor in determining the release paper’s performance. Silicone remains the gold standard for most applications due to its excellent release properties, thermal stability, and versatility. Our silicone-coated release papers undergo a meticulous application process to achieve uniform coverage, ensuring consistent release across every inch of the surface. However, we recognize that some industries, such as medical or food, may require alternatives. That’s why we also provide non-silicone coatings, formulated to deliver comparable release characteristics without the risk of silicone contamination. Whether you need a traditional silicone finish or a specialized non-silicone solution, Charmetack has the expertise to deliver.

Release force is another pivotal parameter, defining how easily the liner separates from the adhesive. Measured in grams per inch using industry-standard tests like the Tesa tape test or FINAT method, release force can make or break an application’s efficiency. At Charmetack, we offer a spectrum of release forces to suit diverse needs. A low release force, such as 5 g/in, facilitates effortless peeling—perfect for labels applied at high speeds. Conversely, a higher release force, up to 100 g/in, ensures the liner remains secure during complex manufacturing processes, such as tape production. Our advanced coating systems allow us to fine-tune this parameter with precision, providing you with a release paper that performs exactly as intended.

Thickness and dimensions further enhance the customization potential of our release papers. Ranging from as thin as 50 microns for lightweight labels to as robust as 150 microns for industrial uses, our products are available in various thicknesses to balance flexibility and strength. We also supply release paper in rolls of varying widths and lengths, tailored to fit your production equipment. Need a specific size for your labeling machine or a custom roll length to streamline your workflow? Our team is ready to collaborate with you to create a solution that integrates seamlessly into your operations.

To give you a clearer picture of how our products differ, the table below compares the key technical specifications of our core release paper offerings:

| Product Name | Base Paper Type | Coating Type | Release Force Range (g/in) | Thickness Range (microns) | Typical Applications |

|---|---|---|---|---|---|

| Glassine Release Paper | Glassine | Silicone | 5-50 | 50-100 | Labels, tapes |

| Kraft Release Paper | Kraft | Silicone | 20-100 | 80-150 | Industrial adhesives |

| Clay-Coated Kraft Release Paper | Clay-Coated Kraft | Silicone | 10-80 | 70-120 | High-end labels |

| Specialty Release Paper | Varies | Non-Silicone | Custom | Custom | Medical, food |

At Charmetack, our role as custom release paper manufacturers extends beyond providing products—it’s about partnering with you to solve problems and enhance your processes. From the selection of base paper to the calibration of release force, every aspect of our release paper is designed with your success in mind. Stay tuned as we explore the manufacturing process, real-world applications, and the environmental advantages of choosing Charmetack’s release paper in the sections ahead. For now, we invite you to reach out via our contact page to discuss how we can support your adhesive needs with our expert solutions.