If you’re coating, laminating, die-cutting, or converting pressure-sensitive materials, the release liner is not “just a backing.” It directly affects release stability, production speed, scrap rate, and the final feel of your label, tape, or protective film. That’s why many converters and brand owners now treat release liners as a controlled component—especially when switching adhesives, increasing line speed, or exporting to markets that demand consistent performance.

What We Manufacture: Silicone Coated Paper & Film Release Liners

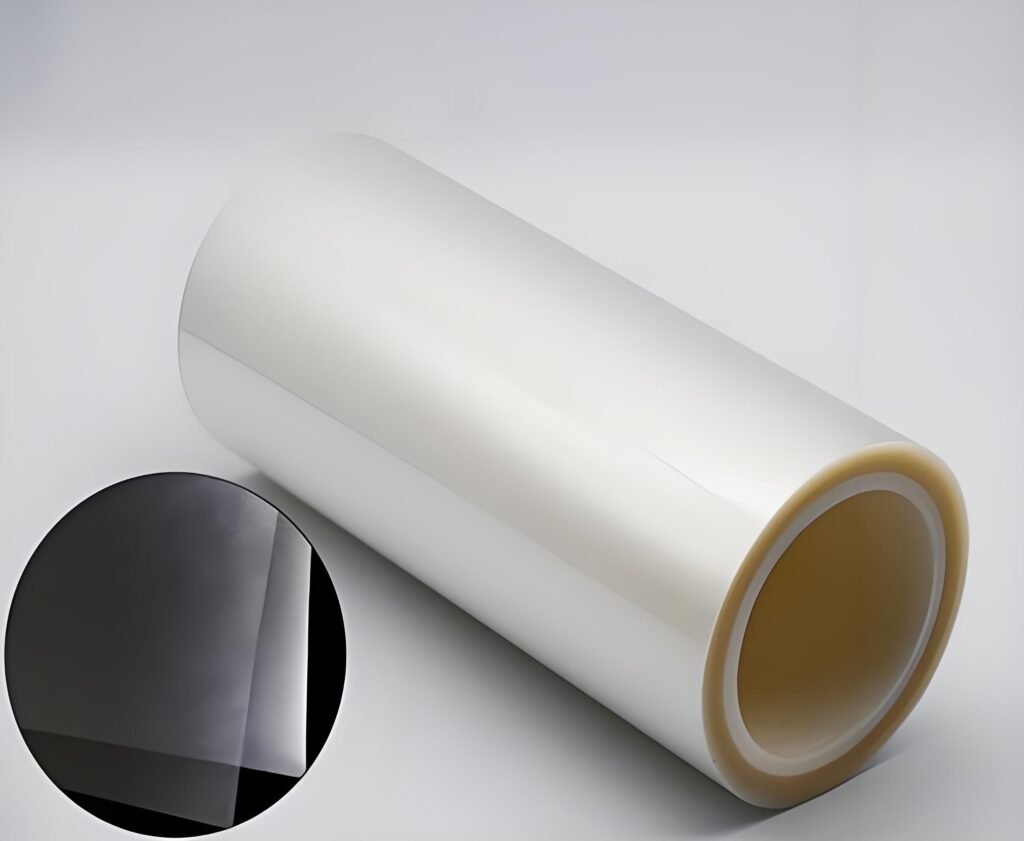

We supply release liner materials in both silicone coated paper and silicone coated film, designed for stable release and smooth converting:

Silicone Coated Paper: glassine, CCK (clay coated kraft), PE-coated kraft (PEK), embossed/air-groove liners, and other industrial base papersSilicone Coated Film: PET release film, BOPP release film, and customized film structures for special converting needs

You can order jumbo rolls or finished slit rolls, and we can match your target release behavior from light to heavy release depending on your adhesive and process.

Why “Release Force” Matters More Than Many People Think

Two rolls can look identical but behave completely differently on your line. Release force that’s too light can cause early peel or handling issues; too heavy can lead to tearing, uneven peel, adhesive transfer, or die-cutting defects.

We help you define release force based on:

Adhesive type (acrylic / rubber / silicone / hot-melt)Application (labels, double-sided tape, foam tape, protective film, electronics)

Converting method (rotary die-cutting, sheet die-cutting, high-speed slitting)

Storage and environment (heat, humidity, long-term aging)

The goal is simple: stable peel, clean separation, and predictable converting.

Customization Options (OEM-Friendly)

Most buyers don’t need a “standard product.” They need a liner that runs well on their exact process. Typical customization includes:

Release force: light / regular / heavy (single-side or double-side silicone)

GSM / thickness: based on stiffness, die-cutting, and handling requirements

Width & length: custom widths, jumbo rolls, and finished rolls

Core ID: converter-friendly core sizes

Color & surface: white/yellow/kraft or film colors as needed

Printing: simple one-color printing for logos, grid lines, tracking marks (when required)

Precision slitting: tight tolerance slitting for high-speed coating and converting

If you’re unsure which liner structure to choose, we can recommend a workable option quickly once we know your adhesive and target peel behavior.

Our release liners are widely used in:

Self-adhesive labels (paper labels, film labels, logistics/barcode labels)

Industrial tapes (double-sided tapes, foam tapes, mounting tapes)

Protective films (surface protection for metal, plastic, glass, electronics)

Electronic materials (stable release and clean peel requirements)

Industrial lamination (release layer for composite materials)

A Practical Selection Checklist (Send This to Your Team)

To reduce sampling rounds and speed up quoting, share these details when you inquire:

Application (label / tape / protective film / electronics)

Adhesive type and coating weight (if known)

Target release level (light/regular/heavy) or your current liner specs

Base preference (paper vs PET/BOPP)

Required GSM/thickness and width

Jumbo roll or slit roll size, and core ID

Any special needs (heat resistance, low shrinkage, clean-room, embossing)

With this information, we can propose a suitable structure and arrange samples for trial runs.

Ready to Quote?

If you want a liner that runs smoothly on your converting line, send:

Your adhesive type

Target release level

Slitting size (width)

Jumbo or finished roll requirements

We’ll recommend a matching liner structure and provide a factory quotation.

FAQ (10)

1) What’s the difference between silicone coated paper and silicone coated film?

Paper liners are cost-effective and widely used for labels and tapes; film liners (PET/BOPP) offer higher dimensional stability, better heat resistance, and cleaner converting in demanding processes.

2) Can you customize release force for my adhesive?

Yes. We tune silicone coating and surface treatment to match different adhesives and target peel performance.

3) Do you supply single-side and double-side silicone coating?

Yes. Both are available depending on your product structure and converting method.

4) What widths can you slit to?

We support custom widths for both jumbo rolls and finished rolls. Share your target width, tolerance requirement, and core ID.

5) What is a jumbo roll and why do converters prefer it?

Jumbo rolls reduce changeovers and cost for coating/laminating lines, then get slit into finished rolls according to downstream orders.

6) Which liner is commonly used for die-cutting labels?

Glassine and PET release liners are common choices. The best option depends on die-cutting speed, adhesive type, and required stiffness.

7) Can you provide embossed/air-groove release liners?

Yes. Embossed liners help reduce bubbles and improve application performance in certain tape and film applications.

8) What information do you need to recommend the right liner?

Application + adhesive type + target release level + width + roll format (jumbo/slit) are usually enough to start.

9) Can you offer samples before mass production?

Yes. We typically arrange samples for trial runs after confirming your basic requirements.

10) Do you support OEM/ODM packaging or private labeling?

Yes. OEM/ODM support is available, including custom specs, printing, and supply formats.