PE self adhesive protective film from Charmetack is designed for temporary surface protection of metal, plastic, glass and coated surfaces during fabrication, transportation and installation. The film provides reliable protection against scratches, dust, dirt and minor impacts, and can be removed cleanly without residue when the job is finished.

Product Overview

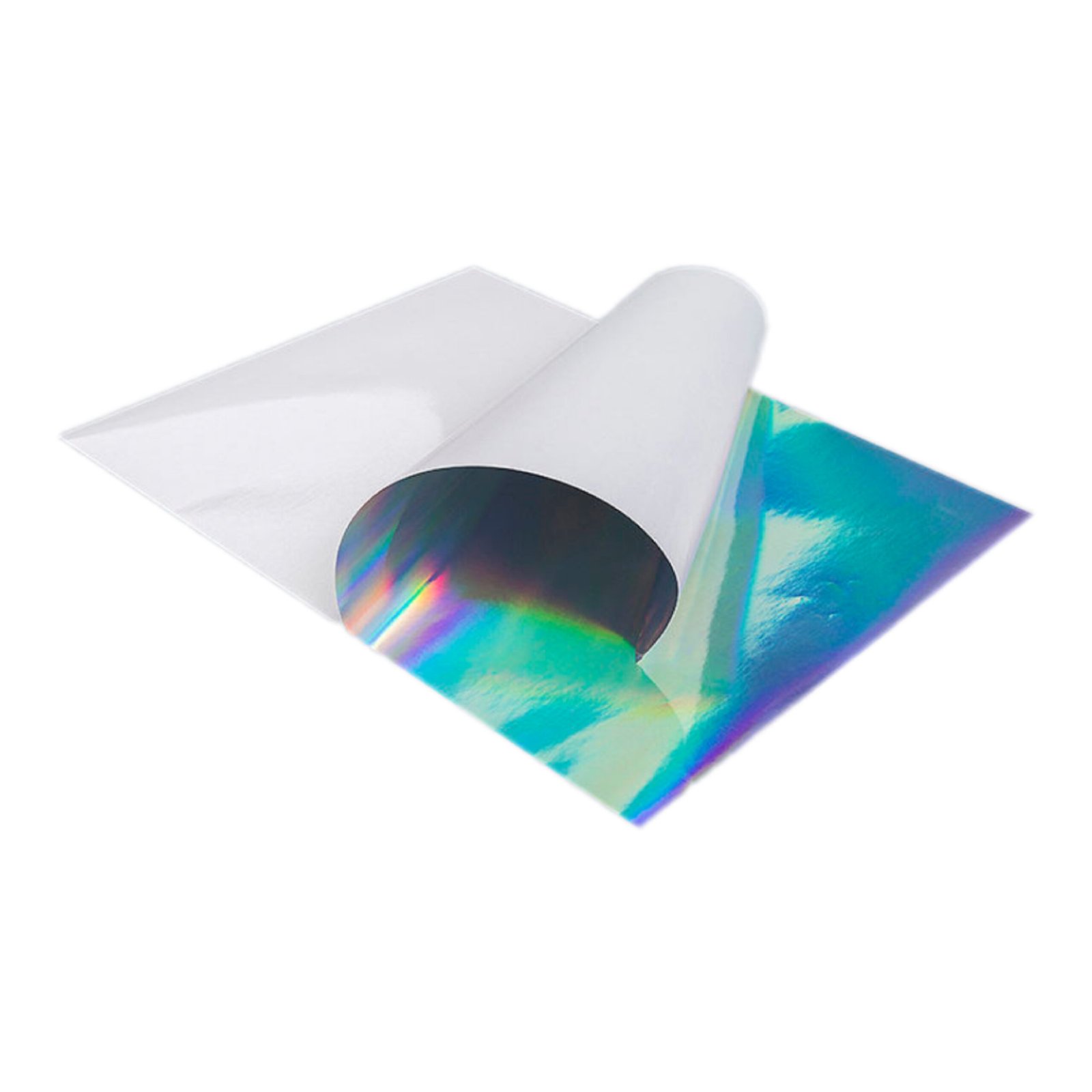

This polyethylene (PE) self adhesive protective film is based on a flexible PE backing coated with a pressure-sensitive adhesive layer. It is engineered to balance secure adhesion during use with easy, residue-free removal, helping you keep finished surfaces in “like-new” condition throughout processing, storage and site work.

Different adhesion levels, thicknesses and colors can be selected to match the surface energy and roughness of the substrate, as well as the handling conditions on site. Charmetack can tailor the product for indoor or outdoor use, short-term or longer-term protection.

Structure & Materials

- Backing film: polyethylene (PE), typically LDPE / LLDPE blend for good flexibility and tear resistance

- Adhesive: pressure-sensitive self-adhesive system, designed for clean removal from compatible surfaces

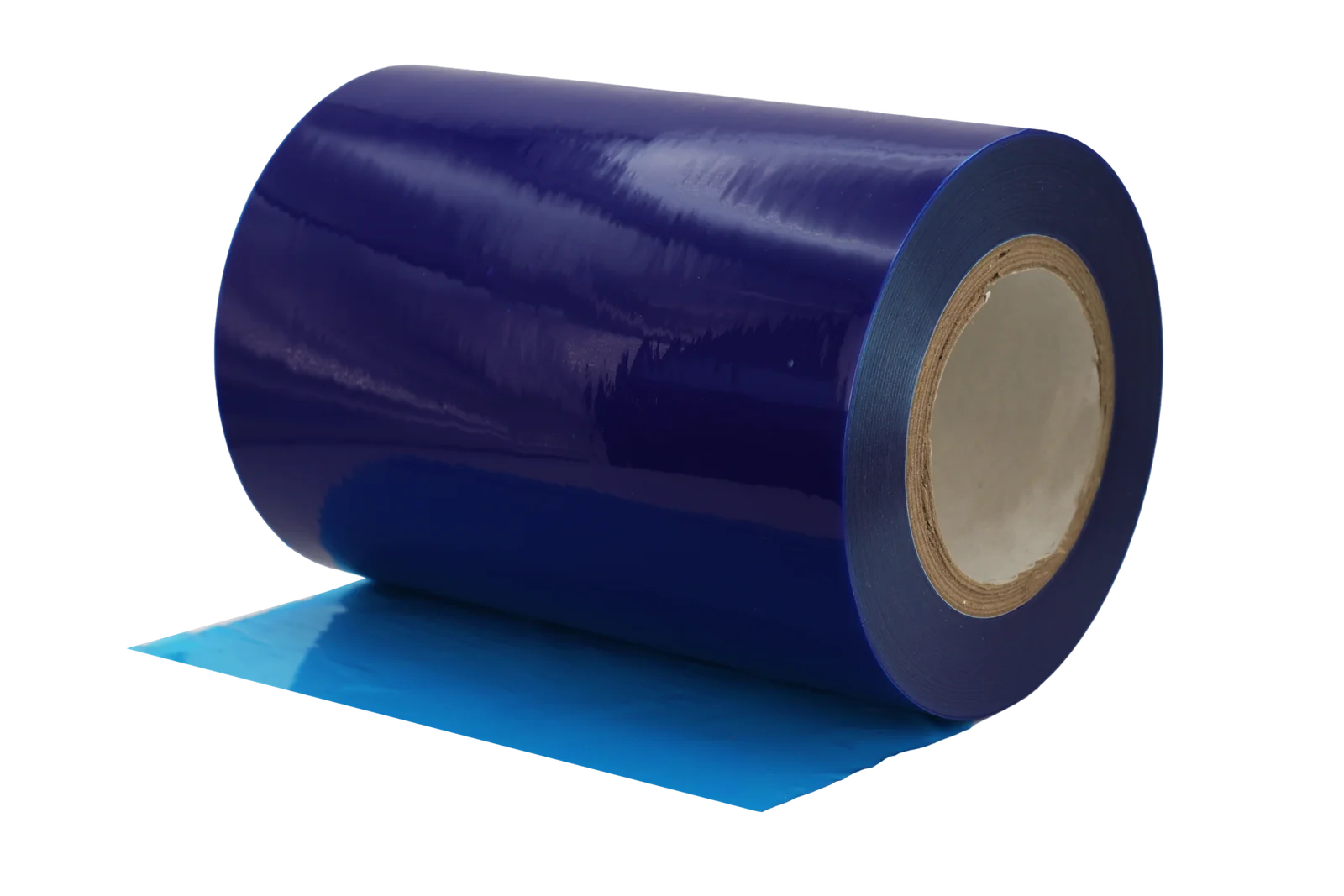

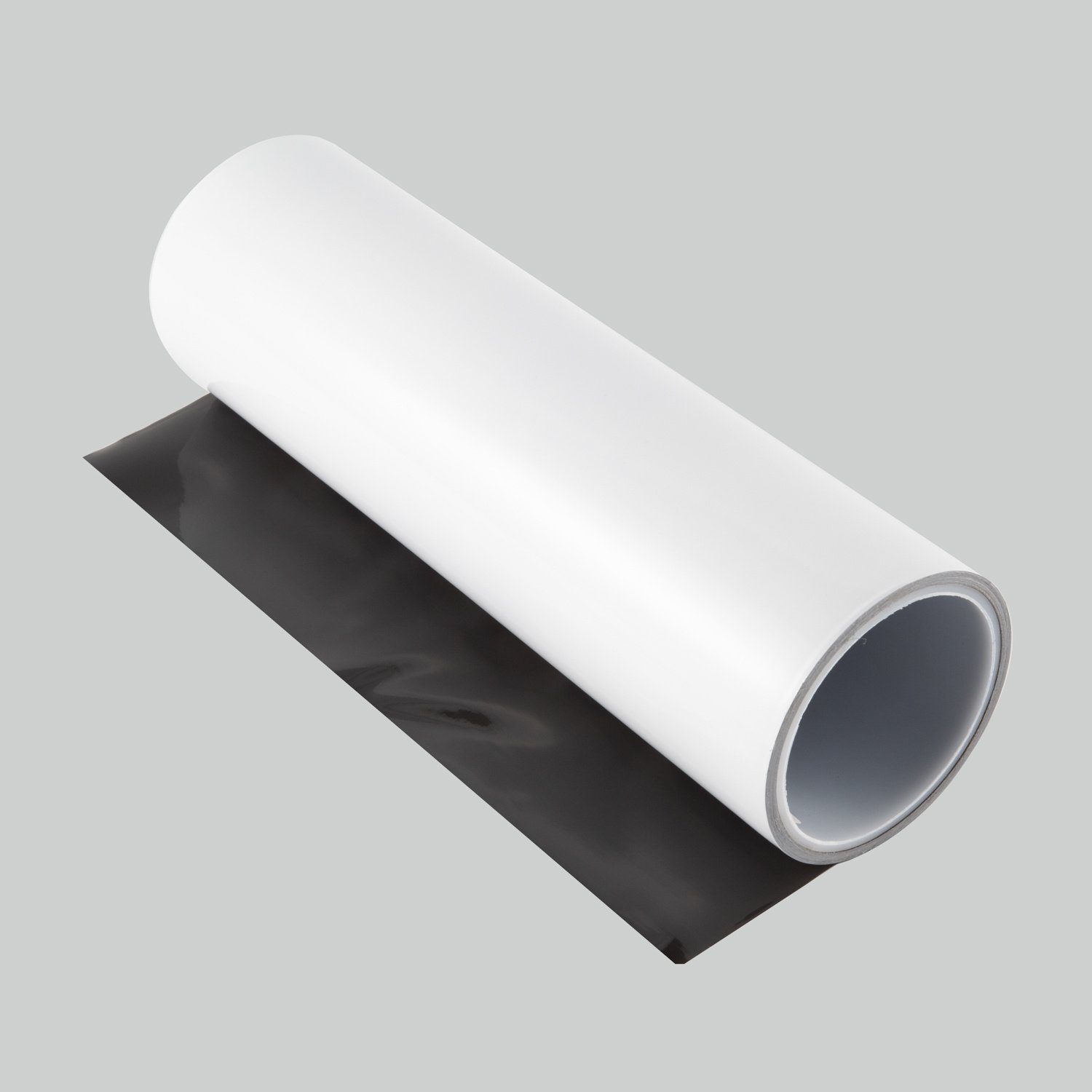

- Color options: transparent, blue, milky white or customized colors

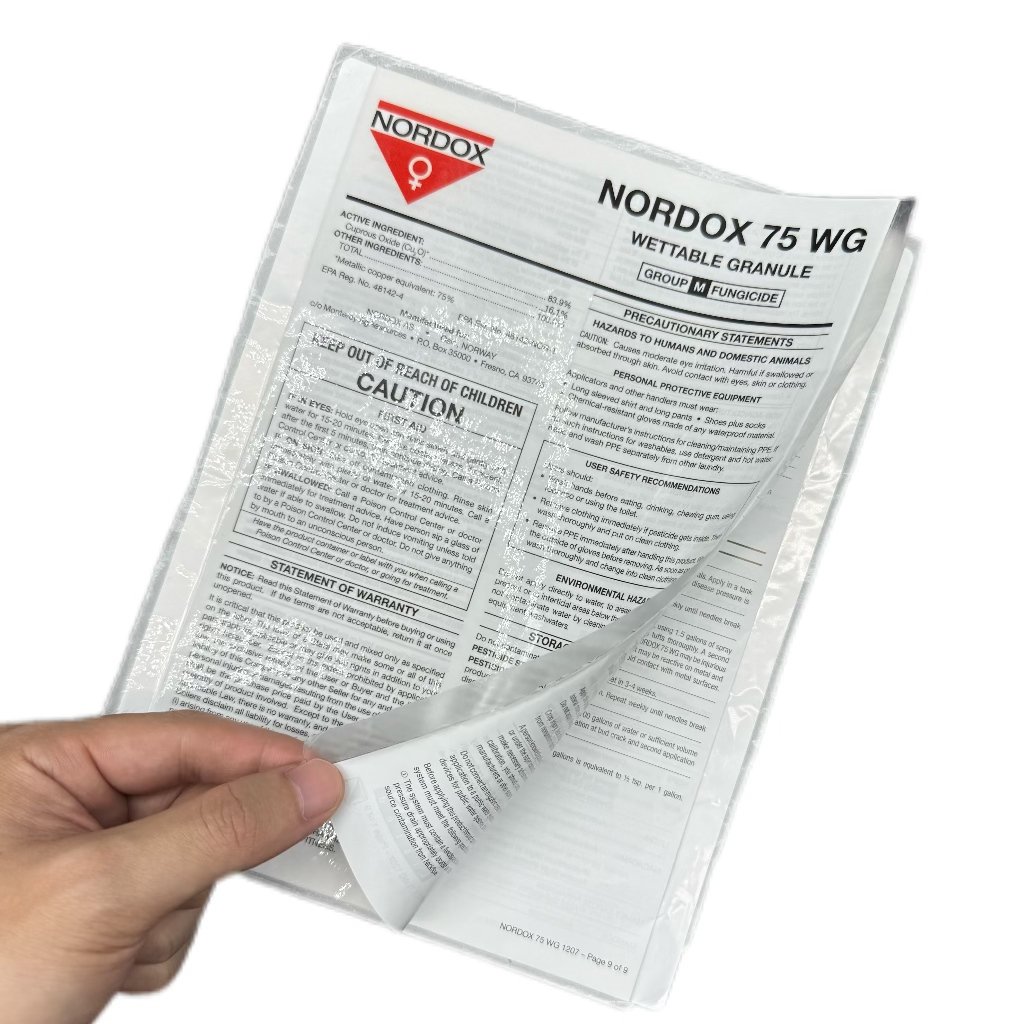

- Printing: optional one-color or multi-color logo, arrows, laying direction or warning text

Typical Applications

Charmetack PE self adhesive protective film is suitable for a wide range of surfaces and industries, including:

- Prepainted and precoated metals: steel and aluminum coils, panels, roofing and cladding sheets

- Stainless steel & metal parts: elevators, appliances, kitchen equipment, architectural metalwork

- Plastic sheets & profiles: PVC, acrylic, PC and other plastic boards and profiles

- Glass & glazing: windows, doors, curtain wall units and glass panels during transport and installation

- Furniture & decorative panels: laminated boards, doors, worktops and finished surfaces

- Flooring & construction surfaces: tiles, stone, laminate and other surfaces needing temporary job-site protection

Key Features & Benefits

- Reliable surface protection: helps prevent scratches, abrasion, dust and light impacts during processing and handling.

- Clean, residue-free removal: adhesive is formulated to peel off smoothly from compatible surfaces when removed within the recommended time.

- Easy application: can be applied manually or on automated laminating lines; good conformability over flat and slightly curved surfaces.

- Multiple adhesion levels: low, medium and higher tack versions available to suit different substrates and paint systems.

- Customizable appearance: choice of film color and printed information to support your brand and installation instructions.

- Cost-effective protection: reduces damage, rework and cleaning, helping to lower total project and warranty costs.

Technical Specifications

Typical specification range (can be customized):

- Film material: polyethylene (PE)

- Thickness: approx. 30–120 μm (1.2–4.7 mil), depending on application

- Standard widths: up to around 1600 mm; slit-to-width service available

- Roll length: typically 100–2000 m per roll, customized on request

- Adhesion level: low / medium / high tack, matched to surface type and removal time

- Color: transparent, blue, milky white or customized

- Application temperature: usually above +10 ℃ for best performance

- Service temperature: suited for typical indoor conditions; outdoor and UV-resistant versions can be supplied on request

Specific data sheets can be provided for each PE protective film grade, including adhesion values, elongation, tensile strength and recommended storage conditions.

How to Choose the Right Protective Film

To select the right PE self adhesive protective film, the following points should be considered:

- Type of surface (stainless steel, coated metal, plastic, glass, etc.) and its surface energy

- Surface finish (high gloss, matte, brushed, textured)

- Processing steps (bending, punching, laser cutting, transport, installation, etc.)

- Duration of protection and storage conditions (indoor / outdoor, humidity, temperature)

- Required thickness and color, and whether logo printing is needed

Charmetack can recommend suitable film grades and conduct sample trials to confirm adhesion and removability on your specific substrates.

Request Samples & Factory Quotation

If you are looking for a reliable supplier of PE self adhesive protective film for metal, plastic, glass or decorative surfaces, Charmetack is ready to support you with stable quality and flexible customization.

Please share the following information so that we can prepare a tailored offer:

- End application and type of substrate

- Surface finish and whether it is painted, coated or polished

- Required film thickness, width and roll length

- Preferred adhesion level (low / medium / high)

- Estimated monthly or annual consumption

Based on your requirements, our team will recommend a suitable PE protective film grade, provide trial samples and offer a competitive factory price for your project.