Views: 7

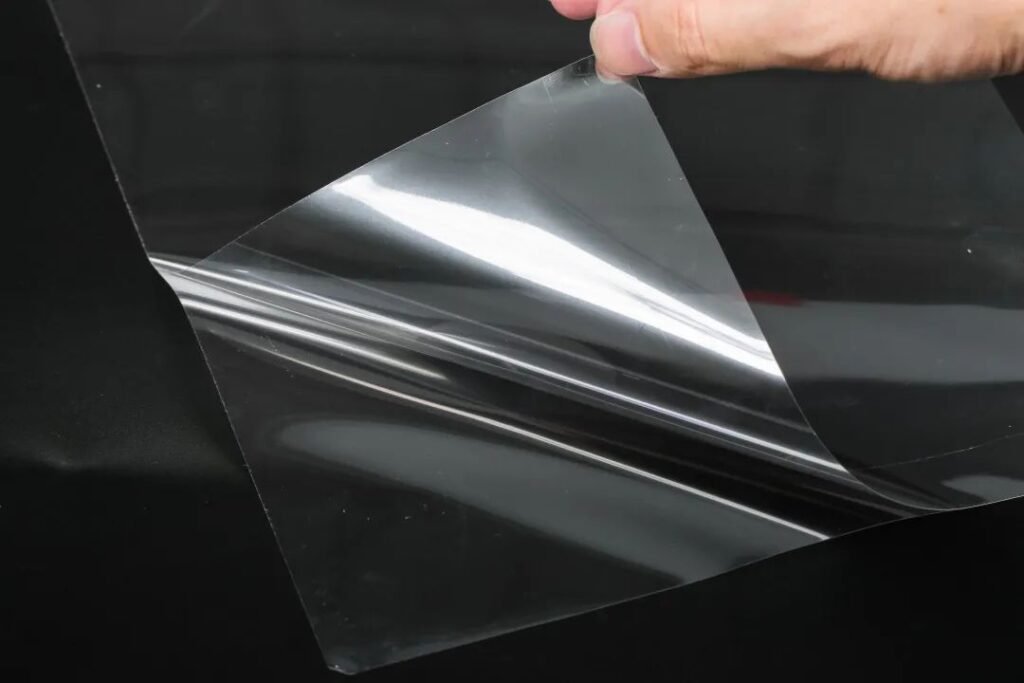

Film labels have many advantages over paper labels, including wear resistance, water resistance, corrosion resistance, good tear resistance, high transparency, and excellent weather resistance. They are now widely used in industries such as daily chemicals, electronics, alcoholic beverages, food, pharmaceuticals, health products, and fast-moving consumer goods. The use of film-based self-adhesive labels has become a trend in the label industry in recent years. The quality, processing, printing, and functional suitability of film labels play a crucial role in the quality of self-adhesive labels.

Common Film Materials Used for Self-Adhesive Labels:

Common film materials include Polyvinyl Chloride (PVC), Polyethylene (PE), Polyester (PET), Polypropylene (PP), and combinations of these.

Principles for Selecting Film-Based Self-Adhesive Labels:

When selecting film materials for self-adhesive labels, it is essential to choose materials that meet the physical and chemical requirements:

- Consider the characteristics of the object being labeled: This includes its type, grade, quality, surface characteristics, usage environment, and user requirements. For example, using a transparent polypropylene film label on a transparent bottle can create a stylish "no-label" effect, enhancing the product's grade. Polyethylene films, with their flexibility, shrinkability, and excellent adhesion properties, are ideal for vivid color displays and large contrasts, attracting attention and promoting the product.

- Smooth, consistent surface: The surface of the film should be smooth and dense, with uniform density, consistent color, and good light transmission. This ensures uniform ink absorption and minimal color differences in prints from the same batch.

- Uniform thickness and strength: The film thickness should be consistent, and its strength must meet the requirements. Printing pressure applied during the printing process is related to film thickness. If the thickness is uneven, the printing pressure will also vary, leading to uneven printing of text or ink color. If the film strength is inadequate, controlling tension during printing becomes difficult, affecting die-cutting and waste removal processes.

- Flatness and uniform rewinding tension: The film should be flat, and the rewinding tension must be even. Good flatness ensures correct material feeding, operation, alignment, and winding during printing. If the rewinding tension is too low, the film may loosen, resulting in misalignment; if it is too high, the material may shrink transversely, causing unstable color registration and difficulties in printing.

- Corrosion resistance, aging resistance, non-fading, and low shrinkage/expansion ratio: If the film has poor corrosion resistance, aging resistance, or fading properties, the labels will not be durable, and this will negatively affect the product’s sale and use. A high shrinkage/expansion ratio can affect printing accuracy and may cause the label to deform during use. This can affect product sales, especially for high-end items, where labels may age before the product expires (aging includes plastic aging and ink fading). If necessary, plastic or label materials should undergo aging tests to assess their performance.

- Film should be within its valid period and stored in a dry environment: The film selected should be within its shelf life and should not be exposed to moisture.

Film Surface Pre-treatment and Effectiveness Testing:

Since most films are non-polar materials with low surface tension, the adhesion of ink and adhesives on their surface is poor. To achieve sufficient adhesion strength, the film material must undergo surface pre-treatment. The most commonly used surface treatment method both domestically and internationally is corona discharge. After corona treatment, the film surface undergoes a series of physical and chemical changes that significantly increase the surface tension, improving the wetting properties of the ink and adhesives, and greatly enhancing the bonding force between them.