Product Description

Charmetack RFID label materials are engineered for high-performance identification, tracking and anti-counterfeiting applications in logistics, warehousing, retail, transportation and manufacturing. By combining durable surface materials, reliable RFID chips and strong adhesive systems, these materials deliver stable reading performance, high mechanical strength and compatibility with a wide range of labeling and converting processes.

Material Composition

Surface material options:

- PP synthetic paper: 38 μm – 200 μm (white), waterproof and tear-resistant, ideal for outdoor or long-life labels.

- PE film: 38 μm – 100 μm (transparent or white), flexible for curved surfaces.

- PET film: 38 μm – 100 μm (transparent or white), high strength and heat resistance.

- Aluminum foil: 25 μm – 50 μm (silver), suitable for anti-tamper or shielding-related label structures.

RFID chip options:

- LF (Low Frequency): 125 kHz – 134 kHz, good penetration and resistance to water/metal interference.

- HF (High Frequency): 13.56 MHz, stable performance for access control, payment and product tracing.

- UHF (Ultra High Frequency): 856 MHz – 960 MHz, long read distance and fast multi-tag reading, ideal for logistics and warehouse systems.

Adhesive material:

- Hot-melt adhesive: Loop tack > 15 N, suitable for application temperatures from -10℃ to 60℃.

Standard width (customizable): 25 mm – 200 mm

Key Features & Benefits

- Wide material selection: multiple face stock options to fit printing, converting and durability requirements.

- Flexible RFID frequencies: compatible with various reader systems and application scenarios.

- Strong bonding: hot-melt adhesive provides firm adhesion on paper, plastic and coated surfaces.

- High durability: moisture-resistant, tear-resistant and suitable for harsh environments.

- Customizable structure: thickness, width, chip type and adhesive strength can be configured per project.

Typical Applications

- Logistics and warehouse management

- Retail product identification and anti-counterfeiting

- Asset tracking and inventory control

- Industrial manufacturing and process management

- Transportation and parcel tracking

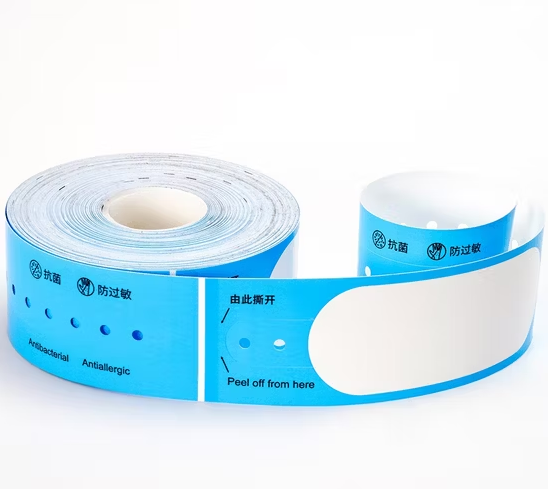

- Library, healthcare and smart-label systems

Request a Customized RFID Label Solution

Charmetack can tailor the RFID label material structure according to your system requirements and usage environment. Please provide:

- Required frequency band (LF / HF / UHF)

- Label size and thickness

- Surface material preference (PP / PE / PET / aluminum foil)

- Application environment and required durability

- Monthly or annual usage volume

We will recommend a suitable RFID label material, prepare samples for testing and offer a competitive factory quotation.

-scaled.jpg)

-scaled.jpg)

-scaled.jpg)