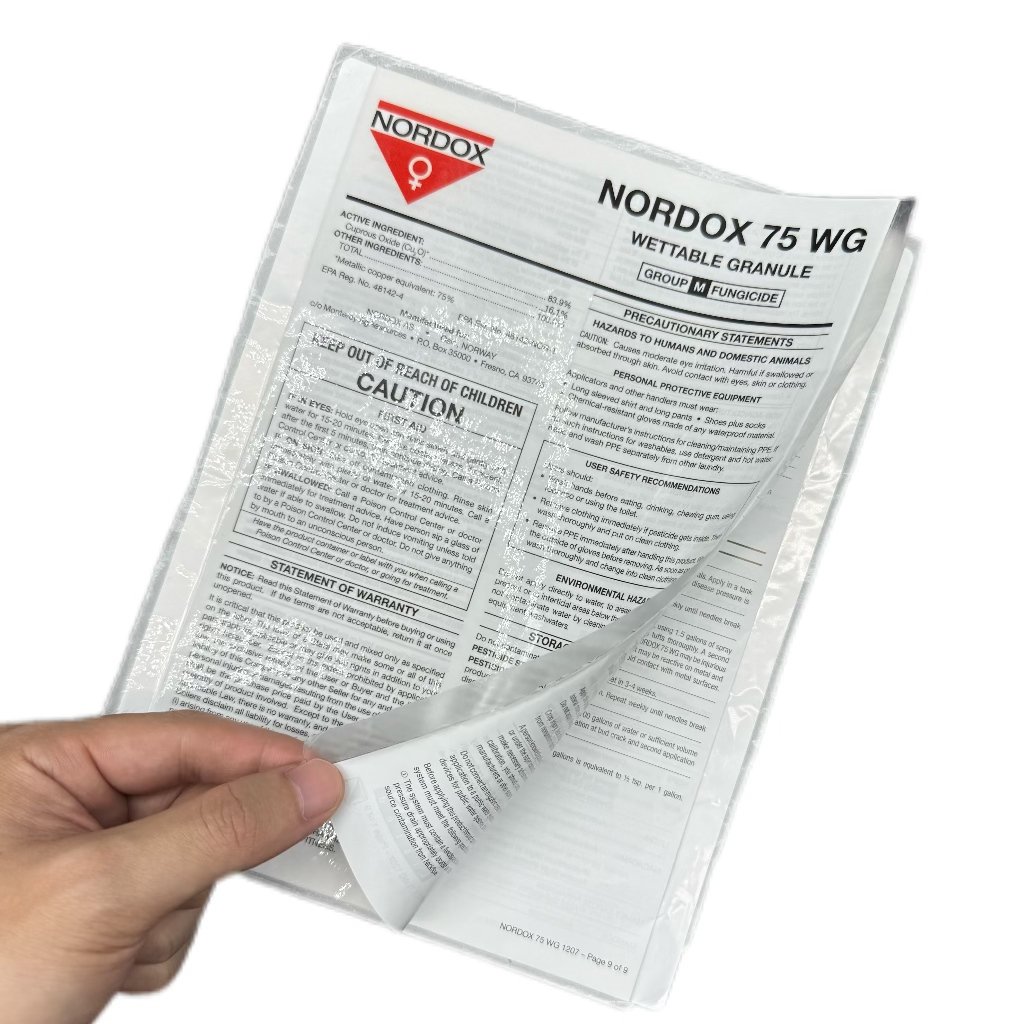

Tire Tread Label Materials (Super High-Tack)

The "Iron Grip" for Rough Tire Surfaces.

Standard labels fail on tires because rubber surfaces are rough, porous, and prone to "chemical migration" (oils/plasticizers). Charmetack’s **Tire Tread Label Materials** are engineered to conquer these challenges.

We use a specialized **Aluminum Barrier Layer** construction that stops tire oils from staining the label face. Paired with our proprietary **High-Flow Rubber Hot Melt Adhesive**, it flows into the tire's micro-tread patterns to create a permanent, non-removable bond.

Engineered for Performance

- Anti-Migration Technology: The hidden aluminum foil layer (laminated between face and adhesive) acts as a shield, preventing sulfur and oils from bleeding through and ruining your brand print.

- Extreme Coat Weight (40-60 gsm): Unlike standard labels (15-20 gsm), our tire glue is extra thick. It acts like "liquid nails," filling the deep gaps in the tire tread for maximum contact area.

- All-Weather Grip: Remains securely attached in freezing winters (-40°C) or scorching summers, ensuring tires arrive at the dealership with labels intact.

- Printer Friendly: Compatible with standard Thermal Transfer (Zebra) and Flexo printing processes.

Technical Specifications

Designed for Post-Mold (After Vulcanization) Application.

| Component | Details |

| Face Stock |

• Aluminized Paper / Silver PET: Premium metallic look with built-in barrier. • White PP / PET: Durable synthetic options for outdoor storage. • FSC Cast Coated Paper: For economical high-gloss printing. |

| Adhesive System |

TS-8000 (Super Aggressive Rubber Hot Melt) • Loop Tack: > 40 N / 25mm (Fera) – Industry Leading Stickiness • Coat Weight: 40gsm – 60gsm (Customizable) • Service Temp: -40°C to +80°C |

| Release Liner |

• Super Calendered Glassine: For automatic high-speed applicators. • Double PE / CCK: For lay-flat manual application sheets. |

| Shelf Life | 12 Months (Stored at 22°C/50% RH) |

Typical Applications

- Passenger & Truck Tires: Brand labels on the tread surface.

- Motorcycle & ATV Tires: High-curvature surfaces requiring flexible facestocks.

- Retreading Industry: Tracking retreaded tires through logistics.

- Rough Surface Labeling: Also works on concrete, carpet, and oily metal drums.

FAQ: Tire Label Materials

Q: Why do I need the Aluminum Barrier?

Without it, the chemicals inside the rubber (plasticizers) will migrate into the paper face, causing it to turn yellow and eventually lose adhesion. The aluminum layer blocks this completely.

Q: Can I print on these with a ribbon?

Yes. Our Art Paper and Synthetic facestocks are compatible with Wax/Resin ribbons. We recommend testing a sample first to ensure barcode scanability on the curved surface.

Solve Your Labeling Headaches

Free Samples for Adhesion Testing.

Tell us: Face Material Preferred + Roll Width