The Cost-Effective Standard for Labels and Tapes.

Charmetack’s Single Side PE Coated Paper (PCK) combines the strength of Kraft paper with the surface smoothness of a Polyethylene (PE) coating. The PE layer fills the microscopic pores of the paper, creating a glass-like surface that requires less silicone while delivering a more consistent release force than standard Clay Coated Kraft (CCK).

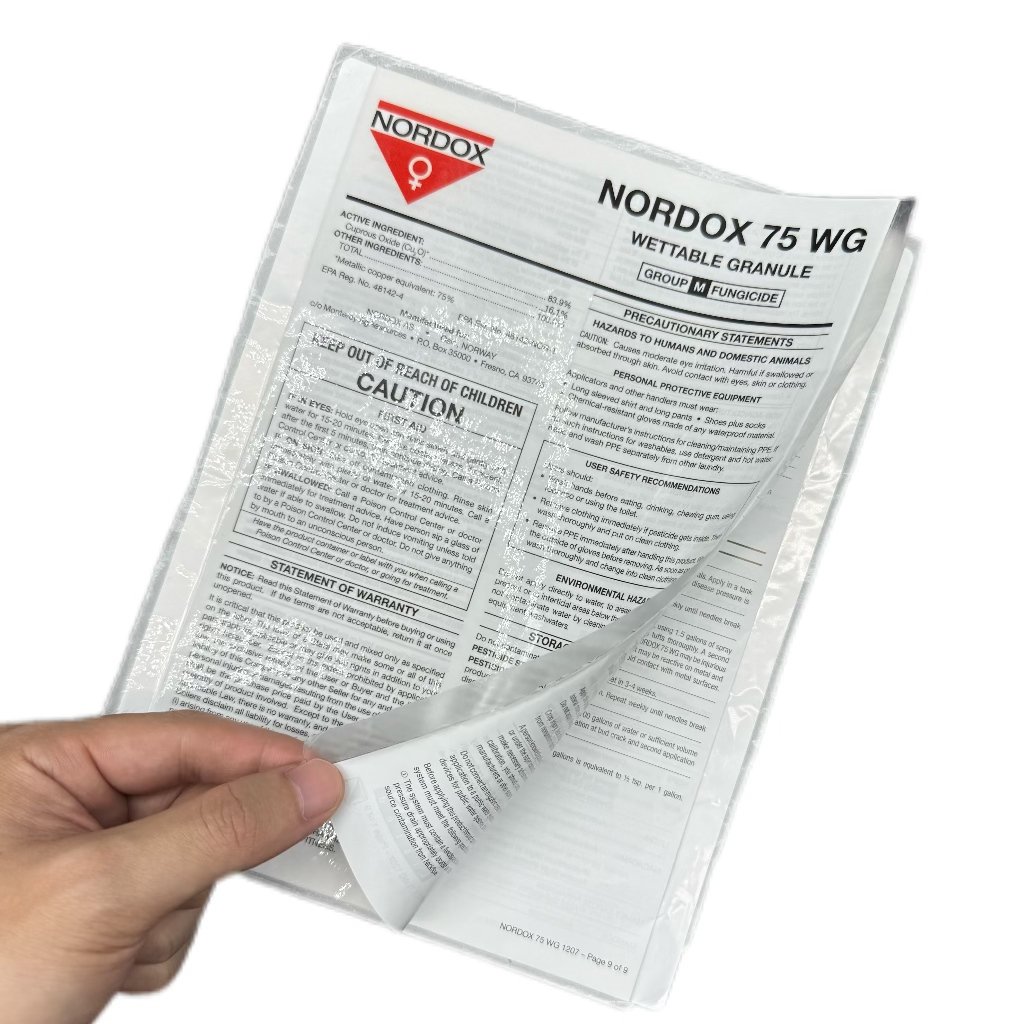

Unlike double-sided liners, the backside remains uncoated raw paper, making it perfect for flexographic printing (logos, instructions, or grids).

Why Choose Our PCK Liner?

- Backside Printability: The non-coated reverse side is suitable for writing or printing branding information, making it ideal for courier labels and instructional tapes.

- Superior Silicone Hold-out: The PE barrier prevents silicone from soaking into the paper fibers, ensuring a 100% effective cure and preventing "lock-up" over time.

- Clean Die-Cutting: The plastic coating acts as a cushion during die-cutting, allowing for "Kiss-Cutting" without dusting or fiber tear.

- Moisture Resistance (Front): The PE side is waterproof, protecting the adhesive layer from humidity ingress.

Technical Specifications

Available in White Woodfree or Yellow/Brown Kraft.

| Property | Details |

| Structure | Silicone / PE Coating / Base Paper |

| Base Paper Types |

• White: Woodfree Paper (60g - 140g) • Yellow/Brown: Kraft Paper (70g - 120g) |

| Release Force |

• Easy Release: 3-10g/25mm • Tight Release: 30-100g/25mm |

| Surface Finish | Glossy or Matte (PE Side) |

| Backside | Rough / Uncoated (Writable & Printable) |

Typical Applications

- Self-Adhesive Labels: Barcode labels, shipping stickers, and price tags where backside printing is needed.

- Industrial Tapes: Single-sided foam tapes, aluminum foil tapes, and masking tapes.

- Medical Products: Release liners for bandages, plasters, and electrode pads.

- Envelope Strips: Finger-lift liners for sealing envelopes and packaging bags.

FAQ: Single Side PCK

Q: What is the difference between PCK and CCK?

PCK (Poly Coated Kraft) uses a plastic PE layer to smooth the surface, offering better moisture resistance and smoother release. CCK (Clay Coated Kraft) uses a clay coating, which is cheaper and better for high-temperature applications but less moisture-resistant.

Q: Can I print on the back of this paper?

Yes. Since the Single Side PE paper has one raw paper side, it accepts ink very well for flexo printing or simple writing.

Need Reliable Liner for Labels?

Get a Factory Quote (PCK Liner).

Tell us: GSM + Width + Do you need Backside Printing?

-1.jpg)

-scaled.jpg)

-1-scaled.jpg)

-scaled.jpg)

-scaled.jpg)

-1-scaled.jpg)

.jpg)