Custom Converting Solutions: From Raw Material to Precision Assembly Parts.

As depicted in our product imagery, Charmetack specializes in the precision converting of functional materials for the 3C (Computer, Communication, Consumer Electronics) industry. We take raw materials—such as foam tapes, double-sided adhesives, and protective films—and die-cut them into intricate shapes with tight tolerances.

Our parts are delivered ready for automated assembly lines, typically utilizing kiss-cutting technology on rolls or sheets with easy-release liners, ensuring efficient application into smartphones, laptops, and wearables.

Key Product Categories Shown

Based on the visual samples, our manufacturing capabilities cover the following key categories:

| Category Visually Represented | Description & Typical Applications |

| Foam Gaskets & Cushioning (e.g., The black foam parts shown) |

Precision die-cut foams (PORON, EVA, PE) used for shock absorption, gap filling, and sealing against dust and moisture. Applications: Camera lens gaskets, speaker meshes, battery cushioning. |

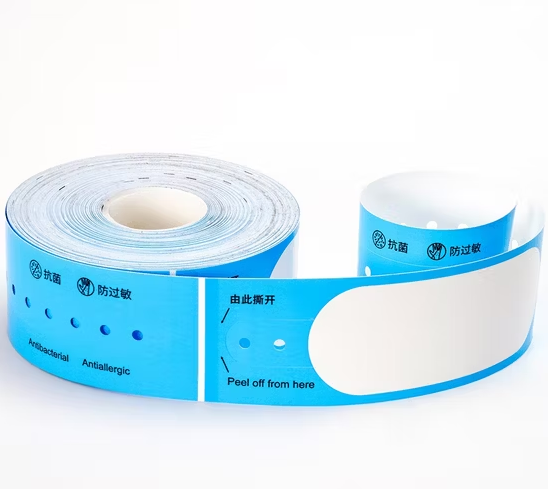

| Adhesive Bonding Tapes (e.g., The tape rolls shown) |

Conversion of double-sided tapes (VHB, PET, Tissue base) into precise shapes for permanent fixing of internal components without mechanical fasteners. Applications: Screen bonding, housing assembly, FPCB fixation. |

| Functional Films & Dielectrics (e.g., The translucent/white parts) |

Die-cut insulating films (PET, PI) or surface protective films designed for specific internal functions or temporary protection. Applications: Electrical insulation layers, temporary screen protection. |

Manufacturing Capabilities

- Precision Die-Cutting: Utilizing rotary and flatbed presses to achieve tight dimensional tolerances required for compact electronic devices.

- Kiss-Cutting: Cutting through the material layer while leaving the liner intact, essential for mass production assembly (as visible in the product photos).

- Multi-Layer Laminating: Combining different substrates (e.g., foam + adhesive + film) before cutting to create complex composite parts.

Typical 3C Applications

Our die-cut components are essential for the functionality and reliability of modern electronics:

- Smartphones: Waterproof sealing gaskets, camera foam, mainboard grounding.

- Laptops & Tablets: Keyboard cushioning pads, trackpad adhesive, thermal management pads.

- Wearables (TWS/Watches): Miniature adhesive seals, acoustic mesh bonding.

Need Custom Precision Parts?

Send us your CAD drawing (DXF/DWG) and material specifications.

We offer rapid prototyping for design verification.

-scaled.jpg)

-scaled.jpg)

-scaled.jpg)